How to choose the suitable Tricone bit by yourself

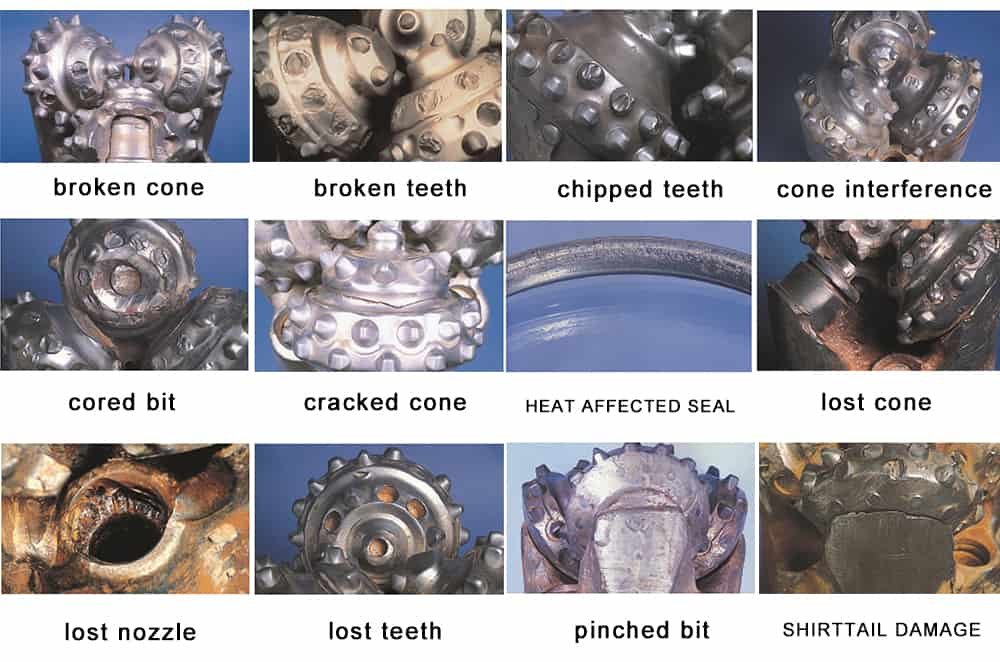

Do you often encounter problems when using drill bits?

- The distress from a Romania customer: An Romania customer once bought a drill bit from his supplier to use in a trenchless engineering project.

- 1. The tooth broke and the bearing was damaged before the 150-meter hit.

- 2. The use time of the drill bit is too short.

- 3. How many meters does the drill bit go deep.

- 4. The drill bearing is broken, the teeth are broken, and the back of the palm is severely worn.

How to choose suitable drill bits by yourself?

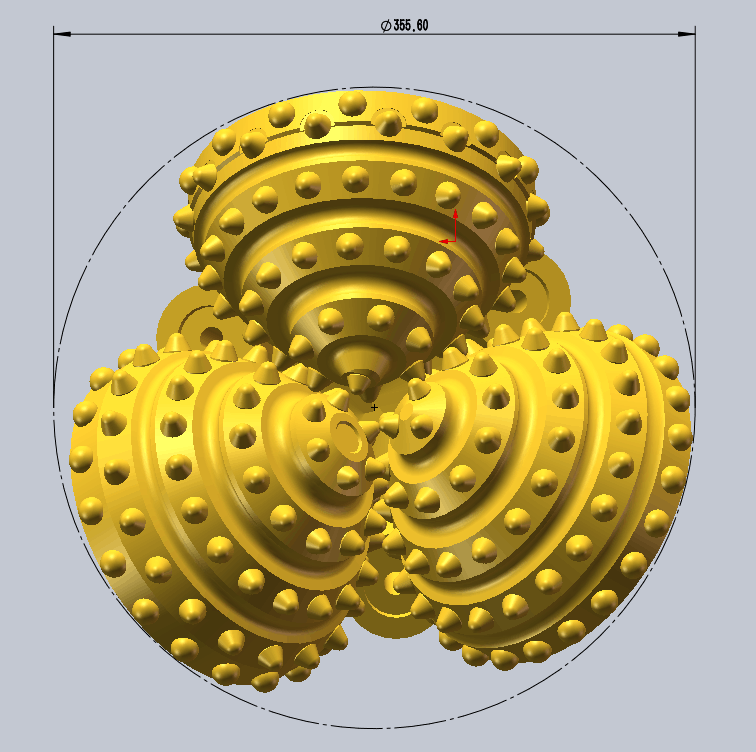

- 1. What are the classification of roller cone bits according to the type of seal?

- Cone bits are divided into metal seals and rubber seals according to the type of seal.

- The metal seal has a fast speed, which is more suitable for oil wells. The slow speed of the rubber seal can be tested in water wells and trenchless projects.

- 2. How to detect metal seals and rubber seals?

- The metal seal turns soft and effortless, while the rubber seal turns harder.

- 3. Cost accounting for metal seals and rubber seals?

- The metal seal is composed of two rubber rings and a metal ring, and the cost is relatively high.

- The cost price of rubber seal is relatively moderate.

- 4. What are the classification of roller cone bits according to the type of bearing?

- Plain bearings (IADC ends with 6/7)

- Rolling bearings (IADC ends in 4/5)

- Open bearings (IADC ends in 1/2), more and more drill bit manufacturers prefer sealed bearing designs.

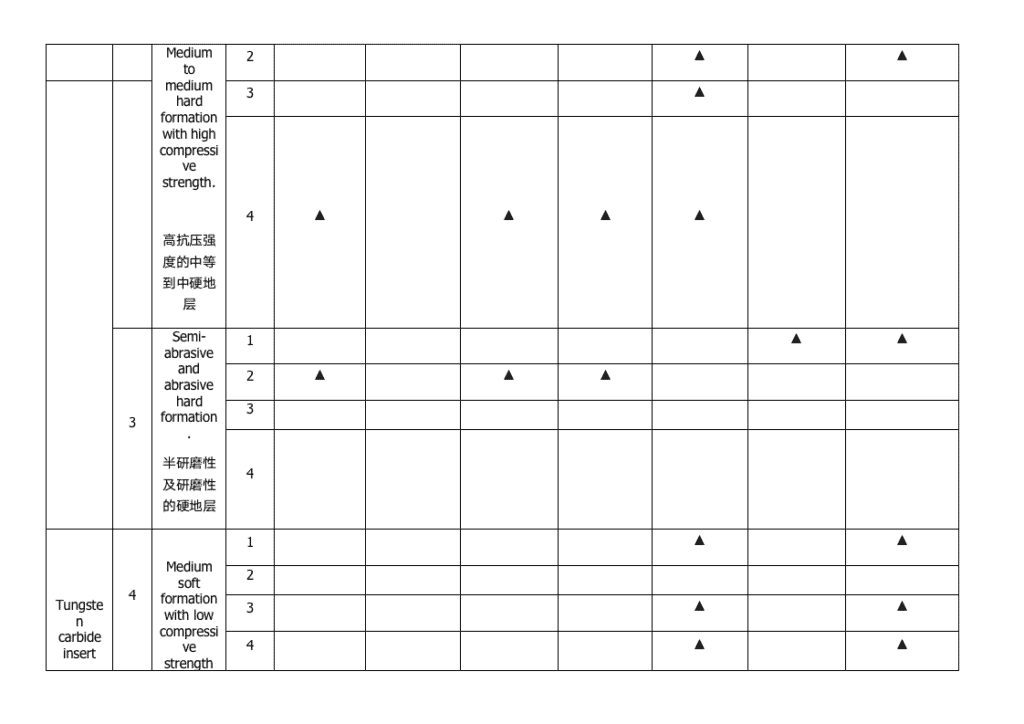

- 5. Choose a suitable drill bit according to the hardness of the drilled formation.

- Different formation hardness corresponds to different IADC codes. The larger the first digit of IADC, the harder the applicable stratum. The larger the second digit, the stronger the crushing ability of rocks. The third digit represents different bearing types.

- According to the compressive strength of different rock formations (PSI/MPa), select the corresponding IADC coded drill bit

- 6. Select the corresponding drill bit according to the drilling pressure and speed of the drill rig

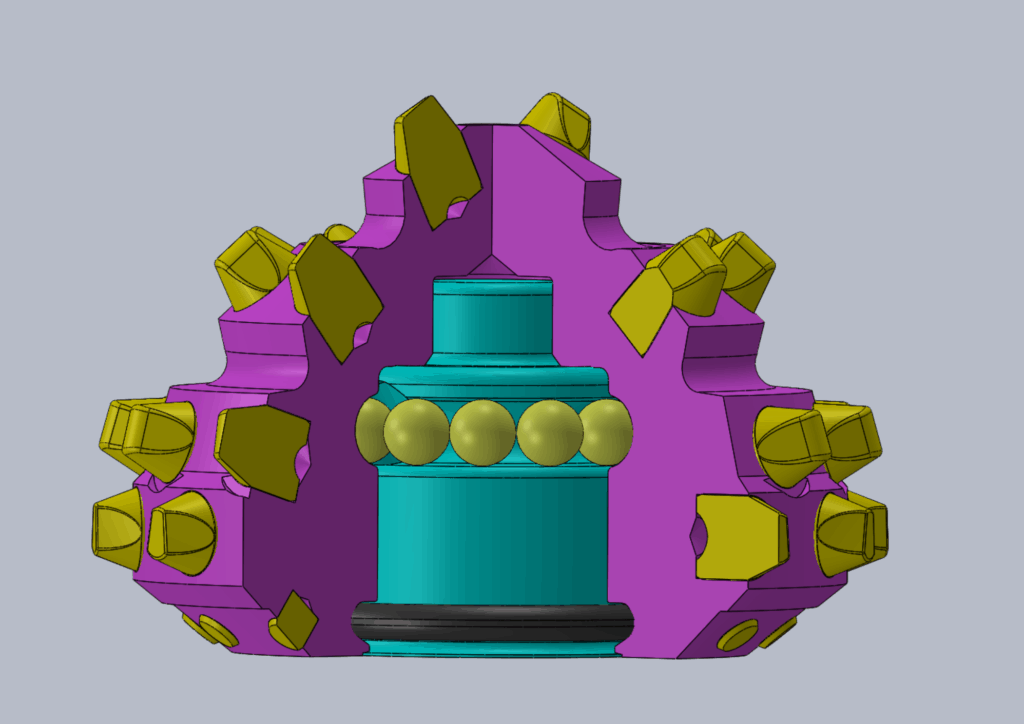

- 7. Choose a suitable drill bit from the aspect of step tooth method, tooth number, tooth profile, and tooth material

- Precise stepping teeth make the alloy teeth more suitable for changes in the formation and improve cutting stability and cutting efficiency

- Choosing a drill bit with reinforced palm cone gauge and palm tip and palm back reinforced gauge will increase the working life of the drill bit.

- Choosing high wear-resistant carbide teeth will also improve the wear resistance and drilling efficiency of the drill

In total, Choose the correct tricone drill bit, it is more helpful for your drilling efficiency, Also a good way for cost-saving